- LED Strip Lights

- 0 likes

- 381 views

Project Overview

This project involved a tunable white LED strip installation where the site already had pre-installed cabling: one single 3-core cable feeding both external runs, and another single 3-core cable feeding both internal runs. The cables were fixed in place, making it impossible to run separate feeds for each zone. This required a custom design approach to ensure correct power delivery, safe operation, and optimised performance without replacing existing wiring.

Key Challenge

A standard installation for multiple LED strip runs would normally use separate power feeds and controllers for each circuit. In this case, only one cable per area was available, so we adapted the design to work within these constraints while still meeting performance requirements.

Technical Solution

We used a pair of 400W 24V IP67 LED drivers (one for the internal runs, one for the external runs), each located approximately 5m from the strips. The original plan was to have the controllers positioned away from the strips, but to reduce voltage drop, we modified the setup:

-

Two cores of the 3-core cable were linked in parallel to carry the 24V line with reduced voltage drop.

-

Controllers were positioned close to the LED strips instead of at the PSU location.

-

Each area was given its own dedicated controller to manage tunable white control.

-

Power was fed in parallel to both the start and end of each LED strip run to ensure even brightness and reduce stress on the LEDs.

LED Strips Used

We selected 14.4W/m tunable white LED strips with two colour channels (warm white and cool white) allowing smooth adjustment between colour temperatures. These strips are factory-supplied with tails at both ends, enabling connection without soldering or connectors if planned cutting is done at the correct cut marks.

Cutting Strategy to Avoid Connectors

By using the factory-supplied tails, soldering and clip connectors could be avoided. For example, an 11m run could be created using:

-

Two complete 5m rolls joined via tails

-

A third 5m roll cut to 1m (at a marked cut line) to complete the run

-

The remaining 4m from that roll can be used for another run or kept as spare

This method ensured all joins were factory-soldered and properly insulated, maintaining product integrity.

Product List Used in This Project

(Search by reference in our website search bar to view each product. Attachments are available on each product page for download, and the Related Products tab lists all compatible connectors and accessories.)

-

LED Strip (Tunable White) – Reference: HL-2835TW-14.4W-IP00

-

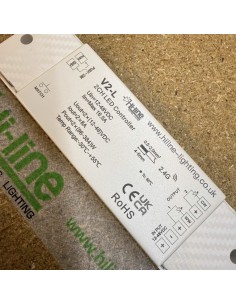

LED Controller (Tunable White) – Reference: HL-V2-L – https://www.hiline-lighting.co.uk/gb/tunable-white-controllers/1114-v2-l-rf-cct-led-strip-controller-5060440718328.html

-

Tunable White RF Remote – Reference: HL-R7 – https://www.hiline-lighting.co.uk/gb/tunable-white-controllers/1088-r7-cct-led-strip-rf-remote-5060440718175.html

-

400W 24V IP67 LED Driver – Reference: HL-400W-24V-IP67-EC-3Y – https://www.hiline-lighting.co.uk/gb/non-dimmable/855-led-driver-600w-24v-ip67-ec-3y-5060440715860.html

-

3-Pin IP68 Connector & Protection Box (5–8 mm) – Reference: HL-3PMC-IP68-508 – https://www.hiline-lighting.co.uk/gb/connectors/1051-3-pin-ip68-connector-protection-box-5-8mm-5060440717727.html

-

Tunable White Wall Panel – Reference: HL-T15-CCT (Optional alternative to remote)

Alternative Best-Practice Design

While this project was successfully adapted to use existing cabling, the best practice for similar multi-run tunable white installations is to use one 200W 24V IP67 LED driver per run.

For 14.4W/m strips, a 200W driver can power up to approximately 11.5 metres (200 ÷ 1.2 ÷ 14.4). This approach reduces strain on components, improves voltage stability, and simplifies wiring.

200W LED Driver: https://www.hiline-lighting.co.uk/gb/non-dimmable/145-led-driver-200w-24v-ip67-premium-series-5060440711442.html

Installer’s Note

Cut LED strips only at the marked cut points to avoid damage. Always test each section before final installation.

Disclaimer

Hi-Line Lighting supplies products only and does not provide on-site installation, technical consultancy, or full lighting design services. This case study is provided as general guidance based on similar constraints. All calculations, wiring layouts, safety checks, and regulatory compliance must be carried out and verified by a qualified installer. Incorrect design or installation can lead to overheating, equipment damage, or risk of fire.

If you do not have your own lighting designer or consultant and would like assistance, please contact us. We work with trusted external partners who can provide professional consultancy and design services for larger or more complex projects.

Need Help With Your Project?

Email support@hiline-lighting.co.uk with your requirements or technical questions. If you receive an automated reply with your ticket number, keep it safe in case you wish to call and discuss further — this also confirms your email was received by our system. If you do not receive this automated reply, please call us to ensure your message was received.