- Dimmable LED Drivers

- 0 likes

- 95 views

- LED dimming, LED strip dimming, wall dimmer compatibility

Many customers wonder why an additional controller is sometimes required between their wall dimmer and the LED driver. This is very common when upgrading to LED strips that must dim smoothly and reliably. The reason is simple. Mains dimming is not a standardised protocol, and this creates inconsistent results with LED lighting.

This article explains why dimmers can fail with LED systems, why drivers behave differently, and how Hi-Line’s dimmer interface controllers ensure smooth and stable dimming. Product references and examples are included for clarity.

Why wall dimmers and LED lighting are often incompatible

Traditional dimmers were designed for incandescent lamps. These lamps dim by reducing voltage. LED lighting does not work this way. LED strips and LED bulbs rely on electronic drivers that expect a stable and predictable dimming signal. Since mains dimming has no universal standard, manufacturers use different internal electronics.

This leads to common issues such as:

Flickering

Buzzing

Lights switching off too early

Limited dimming range

Dead spots where nothing happens

Lights not responding

Even when a dimmer is listed as compatible, actual results depend on the wiring layout, load type, cable lengths and the dimmer model already installed.

Why LED strips require even better control than LED bulbs

LED strips often operate at much higher loads than LED bulbs. A strip installation can run 10, 15 or even 20 metres. The driver must handle high current and maintain stable output. Many wall dimmers cannot communicate correctly with such loads, which is why even high quality dimmable drivers can behave unpredictably.

Hi-Line’s premium mains dimmable drivers are engineered for wide compatibility, but even the best driver cannot correct a poor or unstable dimmer signal. The dimmer is normally the weakest link in the system.

How Hi-Line solves this issue: using a controller between the dimmer and the driver

To avoid compatibility problems, Hi-Line recommends placing a dimming interface controller between the wall dimmer and the LED driver. The controller reads the dimming signal from the wall dimmer and converts it into a clean and stable command that LED drivers and LED strips can understand.

This method improves the entire system and gives:

Smooth and stable dimming

No flicker

Silent operation

Better low brightness control

Much wider compatibility with dimmer brands

Reliable performance with long LED strip runs

There are two main types of systems.

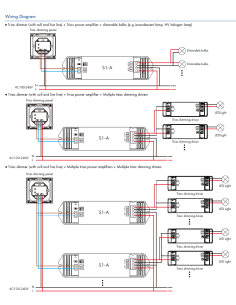

Example System 1: Mains dimmer with hybrid dimmable driver

In this setup, the wall dimmer sends its signal to a controller that stabilises the dimming signal before it reaches the LED driver.

Phase Cut Dimming Extension Module

Reference: HL-S1-A

https://www.hiline-lighting.co.uk/gb/single-colour-controllers/1167-phase-cut-dimming-extension-module-240v-600w-5060440718816.html

This controller then feeds a hybrid dimmable LED driver such as:

Hybrid Dimmable LED Driver 24V 300W IP67 Premium Series

Reference: HL-10VT300W-24V-IP67-GF-5Y

https://www.hiline-lighting.co.uk/gb/hybrid-dimmable/1041-hybrid-dimmable-led-driver-24v-300w-ip67-ec-5060440717666.html

This is an example. The LED driver must always be matched to the total LED load. For a project using around 255W of COB strip, a 300W driver is required. Smaller drivers cannot support long or high intensity strip runs.

Example System 2: Non dimmable driver with low voltage dimmer interface

In this method, the LED driver is non dimmable. The dimming takes place on the low voltage side through the controller.

Mains Dimmer LED Interface 12 to 48VDC 15A

Reference: HL-V1-S

https://www.hiline-lighting.co.uk/gb/single-colour-controllers/1169-mains-dimmer-led-interface-12-48vdc-15a.html

Powered by a non dimmable 300W driver such as:

300W 24V IP67 Driver Premium Series

Reference: HL-300W-24V-IP67-5Y

https://www.hiline-lighting.co.uk/gb/non-dimmable/147-led-driver-300w-24v-ip67-premium-series-5060440711435.html

or

300W 24V IP20 Driver EC Series

Reference: HL-300W-24V-IP20-EC

https://www.hiline-lighting.co.uk/gb/non-dimmable/984-led-driver-300w-24v-ip20-ec-5060440717314.html

The controller performs the dimming, so the LED driver does not need to be dimmable.

The HL-S1-A mains input and mains output controller

Ideal for GU10 lamps and LED strips

Hi-Line also offers a controller that operates on the mains side.

Reference: HL-S1-A

https://www.hiline-lighting.co.uk/gb/single-colour-controllers/1167-phase-cut-dimming-extension-module-240v-600w-5060440718816.html

This unit takes 240V AC in from the customer’s wall dimmer and outputs a stabilised 240V AC signal to the connected LED load. The wall dimmer is used only as a signal. The HL-S1-A carries the real electrical load.

This is extremely useful when:

The wall dimmer is not rated for the actual load

The dimmer is older or incompatible with LEDs

Multiple GU10 lamps are connected

Large LED strip drivers are used

The customer wants to keep their existing dimmer

Because the dimmer only sends the control signal, you can have situations such as:

If a wall dimmer is rated for only 100W, you can still control a 300W load through the HL-S1-A, because the controller handles the real power and the dimmer only instructs it.

This applies to both GU10 lamps and high power LED strip systems.

Why using a controller gives the most reliable result

The controller acts as a compatibility bridge. It ensures that:

The wall dimmer can be almost any brand

The LED driver receives a clean and stable dimming signal

The lighting system performs correctly even with long or high power loads

It removes the weak point in the chain, which is nearly always the dimmer.

Driver examples are only examples

Driver sizes must always match the LED strip load

In the examples above we used 300W drivers because the project involved around 255W of COB strip. Driver sizes must always exceed the load. Examples:

50W LED strip may use a 100W driver

120W LED strip may use a 150W driver

200 to 300W LED strip may use a 300W or 400W driver

Every installation must be calculated individually.

Important installation note

LED strip systems require correct wire gauge, power injections and voltage drop calculations by a qualified installer. Incorrect cables or long feeder runs can cause voltage drop, overheating or fire. Hi-Line supplies the components only and does not provide design or consultancy services. Installations must follow regulations and be carried out by experienced professionals.